The Birth, Death and Legend of Canada's CF-105

Article by Rich Thistle ©

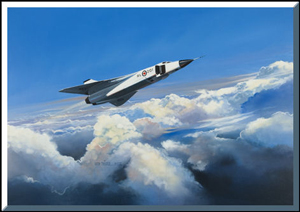

DREAM MACHINE by Rich Thistle© Cool sunlight filtered through a high layer of thin, early-spring cloud. Personnel at fourteen camera stations on and off the airfield at Malton Airport - now Pearson International, Toronto - their equipment double checked and ready, prepared to record Canadian aviation history. Nine thousand aviation workers held their collective breath. It was 9:49 a.m., March 25th, 1958.

DREAM MACHINE by Rich Thistle© Cool sunlight filtered through a high layer of thin, early-spring cloud. Personnel at fourteen camera stations on and off the airfield at Malton Airport - now Pearson International, Toronto - their equipment double checked and ready, prepared to record Canadian aviation history. Nine thousand aviation workers held their collective breath. It was 9:49 a.m., March 25th, 1958.

Just moments before, Avro Chief Development Pilot, and former Spitfire pilot, Jan Zurakowski, had completed his inspection, signed acceptance from the ground crew, climbed the unusually tall boarding ladder and eased himself through the open clam-shell canopy, settling into the cockpit of the world's most advanced aircraft. The straps tightened up. With a final pat on the shoulder, the ground crewman descended and removed the ladder.

Zura was alone with the responsibility now. The plans, hopes and dreams of Canada’s developing aircraft industry were riding with him today. Tens-of-thousands of parts, five miles of cable, hundreds of hydraulic and electronic components, servos and micro switches - most of which had been purpose-designed for this aircraft and all representing the cutting edge of aviation research and technology - would have to function with near perfection. And, to add to the weight, most of this technology was well out of the pilot's direct control. Zura completed engine start-up, acquired flight clearance, and taxied out to his hold position at the end of Malton's newly extended 11,050 foot runway, #32 (320o). Final checks complete, the aircraft moved onto the runway and began to roll.

Article by Rich Thistle ©

DREAM MACHINE by Rich Thistle© Cool sunlight filtered through a high layer of thin, early-spring cloud. Personnel at fourteen camera stations on and off the airfield at Malton Airport - now Pearson International, Toronto - their equipment double checked and ready, prepared to record Canadian aviation history. Nine thousand aviation workers held their collective breath. It was 9:49 a.m., March 25th, 1958.

DREAM MACHINE by Rich Thistle© Cool sunlight filtered through a high layer of thin, early-spring cloud. Personnel at fourteen camera stations on and off the airfield at Malton Airport - now Pearson International, Toronto - their equipment double checked and ready, prepared to record Canadian aviation history. Nine thousand aviation workers held their collective breath. It was 9:49 a.m., March 25th, 1958. Just moments before, Avro Chief Development Pilot, and former Spitfire pilot, Jan Zurakowski, had completed his inspection, signed acceptance from the ground crew, climbed the unusually tall boarding ladder and eased himself through the open clam-shell canopy, settling into the cockpit of the world's most advanced aircraft. The straps tightened up. With a final pat on the shoulder, the ground crewman descended and removed the ladder.

Zura was alone with the responsibility now. The plans, hopes and dreams of Canada’s developing aircraft industry were riding with him today. Tens-of-thousands of parts, five miles of cable, hundreds of hydraulic and electronic components, servos and micro switches - most of which had been purpose-designed for this aircraft and all representing the cutting edge of aviation research and technology - would have to function with near perfection. And, to add to the weight, most of this technology was well out of the pilot's direct control. Zura completed engine start-up, acquired flight clearance, and taxied out to his hold position at the end of Malton's newly extended 11,050 foot runway, #32 (320o). Final checks complete, the aircraft moved onto the runway and began to roll.

Approaching from behind, flaps down, and parallel to the take-off runway were two Royal Canadian Air Force (RCAF) chase aircraft: on the right, an Avro CF-100 Canuck, and on the left, a single-seat F-86 Sabre. Ahead and below, the big, white, delta-wing interceptor responded. As its main gear left the ground, Canada officially entered the era of supersonic flight.

Canada's sleek, new CF-105 Avro Arrow climbed gracefully at a controlled low speed and rate of climb. A routine radio check from the Toronto tower casually marked the historic event. "Avro 201 off at 9:51 a.m. and cleared to company tower." The group of 9,000 Avro workers gathered on the tarmac to watch their creation take to the air, happily congratulated each other, breathing a collective sigh of relief.

For the next half hour, Zura put the Arrow through a set of mild maneuvers, checking control responses, engine performance, undercarriage and air-brake operation and handling at speeds up to 250 knots and at low speed in landing configuration. The automatic flight control system (A.F.C.S.) was tested in normal and emergency modes. The two chase planes stayed close, providing extra sets of eyes.

Zura later recalled that the flying characteristics were similar to other deltas such as the British Gloster Javelin and the American Convair F-102, but that the Arrow had a more positive response to control movement. Letting down in a fairly tight circuit, the Arrow, speed brakes extended, made its landing approach at 180 knots and touched down at 160. The drag chute blossomed, slowing the aircraft. Five minutes later, the Arrow came to a stop on the apron in front of the Avro Plant. The first flight was logged at 35 minutes. Zura climbed down the boarding ladder and was immediately hoisted to the shoulders of jubilant workers. All smiles for the camera were genuine. The dream machine had tried its wings. A Canadian aviation legend was born. The first flight had been almost flawless. Other than two micro switches which had failed to function, the first-flight snag sheet was clean. The engineering department had it framed. The pilot's only complaint was there was no clock in the cockpit!

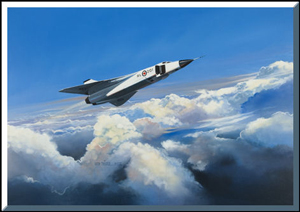

AVRO ARROW by Rich Thistle©After World War II the prevalent Canadian thinking, just as it had at the end of World War I, again placed emphasis on reducing Canadian military forces to a bare minimum and returning to a basically defensive posture behind some of the world's most vast, unpopulated, and difficult-to-defend frontiers, both land and sea. The chief perceived threat, politically, economically and militarily, was the giant Soviet Union which lay just beyond the largely undefended stretches of Canada's far north. The assumption in most quarters was that by 1950, the Soviet Union's aviation industry was up to speed, and that it would be well able to launch a massive conventional and nuclear air strike against populated areas of North America across Canada's Arctic.

AVRO ARROW by Rich Thistle©After World War II the prevalent Canadian thinking, just as it had at the end of World War I, again placed emphasis on reducing Canadian military forces to a bare minimum and returning to a basically defensive posture behind some of the world's most vast, unpopulated, and difficult-to-defend frontiers, both land and sea. The chief perceived threat, politically, economically and militarily, was the giant Soviet Union which lay just beyond the largely undefended stretches of Canada's far north. The assumption in most quarters was that by 1950, the Soviet Union's aviation industry was up to speed, and that it would be well able to launch a massive conventional and nuclear air strike against populated areas of North America across Canada's Arctic.

In this 1952 atmosphere of growing cold war tension Canada decided to search for a replacement for its workman-like, subsonic, Canadian-designed and built Avro CF-100 Canuck interceptor. The Canadian answer would have to respond to a unique set of Canadian circumstances. An interceptor of exceptional abilities would be required to meet the Soviet threat. First, it would have to be capable of operations from widely dispersed bases, over vast, rugged terrain, day or night, in all weather, including near tropical to northern arctic extremes. Furthermore it would have to possess an automatic fire-control system and state-of-the-art weapons of high efficiency and potency.

At the exceptionally high closing rates which would result from the supersonic interception of supersonic bombers, the first-pass kill rate would have to be maximized. A search of Western Alliance manufacturers turned up no extant or developmental aircraft which would fulfill these Canadian requirements, so the decision was taken to develop another all-Canadian interceptor.

In the spring of 1953, Avro began design studies for the most efficient aircraft to meet the Canadian specifications, which included a supersonic combat radius of 200 nautical miles, a combat ceiling of not less than 60,000 feet, a maximum speed at altitude of Mach 2, a rate of climb not more than six minutes to 50,000 feet, internal armament package, twin engines and two crew, and a maneuverability of 2 g at Mach 1.5 at 50,000 feet without loss of speed or altitude. This last requirement could be met by few aircraft even today.

By the summer of 1954, the preliminary design of this aircraft was completed under the project number CF-105. James C. Floyd, Avro Vice-President, and Director of Engineering, led the design team, and the resulting aircraft was, to say the least, unconventional! The RCAF required a two-place design to accommodate a weapons control officer, who could press home an attack even in the event of an automatic mode failure. To handle the large weapons payload required and the huge amounts of fuel necessary for long-range operations, the aircraft would have to be big. The Arrow would be very large, as long as a World War II Lancaster bomber! Two potent engines would be required to power an aircraft of this size.

The tailless high delta configuration was the best compromise between a thin wing section, which could offer excellent transonic and supersonic flight characteristics, and a thicker wing root section to accommodate undercarriage and good fuel capacity. The high delta configuration also offered easy serviceability and good structural efficiency, allowing simple engine installation and easy modifications to engine and armament without affecting the basic wing structure. Also, to the benefit of the design team, considerable delta flight experience and data was available from the British parent company, Avro Manchester, which had been testing the 707 delta research aircraft prior to the design of the Vulcan tailless delta bomber.

Originally, the Canadian Department of Defense Production had issued a design contract for two prototype CF-105's from Avro, but, shortly thereafter, because of the urgency to meet the perceived Soviet threat of bombers from the north, a decision was made to skip the prototype stage altogether and the order was revised. Avro was to go directly to production with several pre-production aircraft. This approach placed considerable pressure on the design team, and a very comprehensive testing program became an obvious necessity. Totally new testing procedures would be used in the Arrow program. Of course, thorough wind tunnel testing became a priority. Through the tunnel test program, the external shape of the Arrow fuselage was refined by application of the 'Area Rule', to give the so-called "Coke Bottle" effect for the purpose of reducing supersonic drag.

Models would also play another vital design role. Launched to supersonic speeds on Nike rocket boosters, eleven free-flight models were fired between December, 1954 and January, 1957, and important data on drag and directional stability collected via the then-emerging telemetric technology. Two firings were conducted at Langley Field, Virginia, the establishment of the National Advisory Committee for Aeronautics (NACA), to take advantage of their complete, state-of-the-art tracking and telemetry equipment.

Considerable stress testing was also carried out on models. All-told, more than seventeen carefully-crafted scale models were used in the extensive design process. As actual production of the first six aircraft approached, a full- sized metal mock-up was fabricated to explore ways of facilitating actual production methods. A full-size wooden engineering mock-up was also constructed to check all equipment installation, fit and tolerances. Production machinery was designed, ordered and installed, much of it new, huge and unprecedented in the aviation industry. Meanwhile an Arrow flight simulator, connected to a state of-the-art analog computer system, the largest at the time outside the United States, was helping to gather theoretical flight characteristic data which would smooth the way to actual flight of the CF-105.

The development of the power plants chosen for the Arrow is a story in itself. The first design called for Rolls Royce RB 106 engines which were under development. When it was found that this development would be too late for the CF-105 program, Curtiss Wright J67's were substituted. Then in 1955, The U. S. Air Force announced the J67 program was to be dropped and Pratt & Whitney J75,s were chosen as a stopgap measure until the new home-grown Orenda PS13 Iroquois engines would be available.

In 1953 the PS13 Iroquois was designed by Orenda Engines Limited, later a division of A.V. Roe Canada, to power the replacement for the Avro Canuck. In a bold step, Orenda decided to jump a generation with its new design. The PS13 was to be big and powerful. At a dry weight of 4,500 lb., the Iroquois would have a five-to-one thrust-to-weight ratio, with 20,000 lb. dry thrust and 26,000 lb. with afterburner. This would create an unprecedented weight-to-thrust ratio of virtually one-to-one in the Iroquois powered Arrow.

This engine's development was not without glitches, but from original design in 1953, the problems were basically ironed out by early 1957. When ground testing was complete, a Boeing B-47 Stratojet was loaned to Avro by the USAF as a flight test bed for the new engine. One Iroquois engine had more than enough power for the B-47.

While A. V. Roe Canada was responsible for the airframe and engine development, the weapons and fire control systems were in the RCA's ballpark. At the beginning of the CF-105 project, it was understood that the package of choice was the American Hughes MX 1179 fire control system and eight Falcon missiles which had been designed for an American fighter program. However, much against the wishes of Avro, the RCAF changed its mind in favor of the Douglas Sparrow II missile then under development for the United States Navy, and the RCA Astra fire control system. This weapons package would make the Arrow more potent than any interceptor in existence. Nothing but the best for the RCAF. But, as they soon found out, it wouldn't be without cost.

By mid 1955, when the RCAF had decided upon this state-of-the-art system, Avro was forced to undertake major re-engineering to accommodate the Astra system, thus adding greatly to the financial burden imposed by the whole project. By this time, tension at Avro was beginning to increase. They knew the Astra system would prove astronomically expensive to develop. Furthermore, now all three components of the Arrow project, airframe, engine and weapons package were new, unproven, and cutting edge. The risks were suddenly much higher.

Then, a major blow to the armament program. The United States Navy dropped the Sparrow II missile project. Against the best advice from Avro, the RCAF, determined to see the best weapons system possible in the CF-105, and, apparently, regardless of the huge investment it would devour, transplanted the whole project, missiles and fire control, to Canada. As it turned out, the development cost of this package would have a significant impact on the overall cost of the Arrow program. Meanwhile, under the darkening cloud of increasing cost exacerbated by the out-of-control weapons development program, and amid growing tension in Avro administration, the airframe/engine development continued apace. The new Canadian interceptor was rolled out of the plant into public view amid glowing speeches from politicians and defense staff on October 4, 1957. According to those on the podium, it would prove more than enough to cancel out the Soviet bomber threat for the next decade.

However, an event of even greater global importance overshadowed the grand unveiling. On the same day, the Soviet satellite Sputnik was successfully launched into orbit. This event created instant, massive, technological hysteria in the west. The Soviets had leap-froged to the forefront again. Ironically, as spiraling costs conspired to sink the whole Arrow project, the successes of the testing program mounted steadily. Ground and taxi trials proceeded smoothly and, on March 25, 1958, Arrow 201 flew for the first time with Zurakowski at the controls.

The short flight-test program was almost trouble free. A couple of minor landing accidents caused by undercarriage failure and a blown tire, and a failure of the nose gear door to close seem minor in comparison to the teething problems experienced in many other fighter development programs even today.

For example, using over fifty aircraft and flying in excess of 8000 test flights, the Lockheed F-104 Starfighter test program was plagued with serious problems from the beginning. Several early 104's and their pilots were lost. Taking into account that the Arrow program never progressed past its infancy and that the five flying CF-105 Arrows accumulated among them only 66 flights and 70 hours of flight time, the fact that there were no serious problems with the aircraft itself is still a testament not only to the young Avro company and its design team, but also to the quality of the four test pilots in the program. Nevertheless, the flight-test program, which lasted less than twelve months, proceeded very smoothly and efficiently. The program was expedited by the use of ground and on-board telemetry data gathering, a technology then in its infancy. The capacious internal weapons bay of the Arrow was crammed with test instruments which allowed immediate in-flight feed-back to the pilot and those on the ground. Today we call this a "real-time" system.

The Arrow would have been an eminently developable aircraft. The introduction of micro-chip technology to replace the heavy onboard vacuum-tube computers would certainly have gained the developed Arrow a weight and space advantage resulting in substantially greater speed and range.

Another technology then in its infancy was the flight control system popularly known as "fly-by-wire". The Avro Arrow was one of the first service aircraft to use this system in which the pilot's movements were translated, via electrical switches in the control column, into electric signals which would then hydraulically introduce the movement called for in the control surfaces themselves.

Superimposed on this system was a sophisticated parallel damping system which moved the surfaces completely independent of the pilot's control column to moderate and "smooth out" the movements called for by the pilot. Eventually, the Arrow was to be able to virtually fly itself - computer controlled - with the pilot as a back-up emergency factor. Well ahead of its time, the Arrow's fly-by-wire system would not be used again successfully on a combat aircraft until the General Dynamics F-16 Fighting Falcon, which flew for the first time in 1974.

It was also the first aircraft to employ a 4000 psi hydraulic system, not replicated in any aircraft until 16 years later in the Rockwell B-1 bomber. In August, 1958, representatives of the Canadian government traveled to the United States, ostensibly to sell the Arrow or to raise funds south of the border to support the program. They came back having missed both targets, themselves the target of a strong American sales-pitch for their own aircraft and the untested American Bomarc missile.

Meanwhile, amid American offers to defend Canadian airspace if the Arrow program were indeed cancelled, the Canadian government, pointing to the costs of the project and downplaying the menace of the Soviet bomb threat, drew closer to terminating the Arrow program with the announcement that the Bomarc nuclear surface-to-air missile was coming to Canada..

Avro responded to the government's warnings of impending cancellation of the program with a final offer of $3.5 M per Arrow based on delivery of 100 aircraft. James C. Floyd, Avro Vice President, Engineering, later called this price " the deal of the century". Included would be the more powerful Iroquois and the Hughes/Falcon weapons system offered to the project just before cancellation, by the USAF at no cost. The Sparrow/Astra system had finally collapsed under its own financial obesity.

Then on February 20, 1959, still known as 'Black Friday' by many Canadians, the CF-105 program was finally cancelled. With the announcement came the direct loss of 14,000 jobs at Avro and Orenda, another 16,000 jobs with Avro's suppliers throughout Canada. It is also calculated that Avro was involved in almost 75% of all Canadian research and development at the time. Also crashing to the ground was the Orenda Iroquois engine program. With the cancellation of the Arrow, the considerable international interest which had been shown in the big engine immediately dried up.

At the time of cancellation, Arrow 206, the first Mk.2, with the Iroquois engine, was two weeks away from its first flight and a short time away from an inevitable attempt at a new world speed record. The Arrow Mk. 2 never flew. Everything relating to the Arrow program was ordered immediately destroyed, scrapped, cut up and carted away. All drawings, tools, photographs, instruments, production machinery, laboratories, and all thirty-seven aircraft - five complete and flying, one ready to fly in just two weeks, and the others in various stages of completion - were ordered destroyed.

When the Arrow program died, thousands of talented people were immediately recruited to companies out of the country. Many former Avro employees, for example, helped to put men on the moon with NASA. Some, including James Floyd, went overseas to work on the Concord project. A body blow had been delivered to Canada's fledgling aviation industry.

It was Thursday, April 25, a bare two months after Black Friday. Janus Zurakowski, the test pilot who first flew Arrow 201 thirteen months before, was on his way home from the Avro plant at Malton on Highway 401. Curiously for a test pilot, he was a nervous driver, careful not to exceed the 60-mph limit. In his rear-view mirror he noticed a truck pulling a flat-bed trailer overtaking him in the passing lane. As the truck pulled along side, he casually noted the load. There seemed something vaguely familiar about the stack of jagged white metal pieces trussed under the tie-downs. Suddenly, as he looked more closely, he made a jolting discovery. There were the numbers "2", "0", and "1" painted in black against jagged white metal pieces. Here, almost unrecognizable, was all that was left of the CF-105 Arrow. The Avro Arrow was dead. But even today, the legend of this world-beating aircraft lives on in the hearts of many Canadians.

SIDE BAR: THE BIRTH, DEATH AND LEGEND OF THE CF-105 ARROW 'A.V ROE CANADA LTD.'

Canada's sleek, new CF-105 Avro Arrow climbed gracefully at a controlled low speed and rate of climb. A routine radio check from the Toronto tower casually marked the historic event. "Avro 201 off at 9:51 a.m. and cleared to company tower." The group of 9,000 Avro workers gathered on the tarmac to watch their creation take to the air, happily congratulated each other, breathing a collective sigh of relief.

For the next half hour, Zura put the Arrow through a set of mild maneuvers, checking control responses, engine performance, undercarriage and air-brake operation and handling at speeds up to 250 knots and at low speed in landing configuration. The automatic flight control system (A.F.C.S.) was tested in normal and emergency modes. The two chase planes stayed close, providing extra sets of eyes.

Zura later recalled that the flying characteristics were similar to other deltas such as the British Gloster Javelin and the American Convair F-102, but that the Arrow had a more positive response to control movement. Letting down in a fairly tight circuit, the Arrow, speed brakes extended, made its landing approach at 180 knots and touched down at 160. The drag chute blossomed, slowing the aircraft. Five minutes later, the Arrow came to a stop on the apron in front of the Avro Plant. The first flight was logged at 35 minutes. Zura climbed down the boarding ladder and was immediately hoisted to the shoulders of jubilant workers. All smiles for the camera were genuine. The dream machine had tried its wings. A Canadian aviation legend was born. The first flight had been almost flawless. Other than two micro switches which had failed to function, the first-flight snag sheet was clean. The engineering department had it framed. The pilot's only complaint was there was no clock in the cockpit!

AVRO ARROW by Rich Thistle©After World War II the prevalent Canadian thinking, just as it had at the end of World War I, again placed emphasis on reducing Canadian military forces to a bare minimum and returning to a basically defensive posture behind some of the world's most vast, unpopulated, and difficult-to-defend frontiers, both land and sea. The chief perceived threat, politically, economically and militarily, was the giant Soviet Union which lay just beyond the largely undefended stretches of Canada's far north. The assumption in most quarters was that by 1950, the Soviet Union's aviation industry was up to speed, and that it would be well able to launch a massive conventional and nuclear air strike against populated areas of North America across Canada's Arctic.

AVRO ARROW by Rich Thistle©After World War II the prevalent Canadian thinking, just as it had at the end of World War I, again placed emphasis on reducing Canadian military forces to a bare minimum and returning to a basically defensive posture behind some of the world's most vast, unpopulated, and difficult-to-defend frontiers, both land and sea. The chief perceived threat, politically, economically and militarily, was the giant Soviet Union which lay just beyond the largely undefended stretches of Canada's far north. The assumption in most quarters was that by 1950, the Soviet Union's aviation industry was up to speed, and that it would be well able to launch a massive conventional and nuclear air strike against populated areas of North America across Canada's Arctic. In this 1952 atmosphere of growing cold war tension Canada decided to search for a replacement for its workman-like, subsonic, Canadian-designed and built Avro CF-100 Canuck interceptor. The Canadian answer would have to respond to a unique set of Canadian circumstances. An interceptor of exceptional abilities would be required to meet the Soviet threat. First, it would have to be capable of operations from widely dispersed bases, over vast, rugged terrain, day or night, in all weather, including near tropical to northern arctic extremes. Furthermore it would have to possess an automatic fire-control system and state-of-the-art weapons of high efficiency and potency.

At the exceptionally high closing rates which would result from the supersonic interception of supersonic bombers, the first-pass kill rate would have to be maximized. A search of Western Alliance manufacturers turned up no extant or developmental aircraft which would fulfill these Canadian requirements, so the decision was taken to develop another all-Canadian interceptor.

In the spring of 1953, Avro began design studies for the most efficient aircraft to meet the Canadian specifications, which included a supersonic combat radius of 200 nautical miles, a combat ceiling of not less than 60,000 feet, a maximum speed at altitude of Mach 2, a rate of climb not more than six minutes to 50,000 feet, internal armament package, twin engines and two crew, and a maneuverability of 2 g at Mach 1.5 at 50,000 feet without loss of speed or altitude. This last requirement could be met by few aircraft even today.

By the summer of 1954, the preliminary design of this aircraft was completed under the project number CF-105. James C. Floyd, Avro Vice-President, and Director of Engineering, led the design team, and the resulting aircraft was, to say the least, unconventional! The RCAF required a two-place design to accommodate a weapons control officer, who could press home an attack even in the event of an automatic mode failure. To handle the large weapons payload required and the huge amounts of fuel necessary for long-range operations, the aircraft would have to be big. The Arrow would be very large, as long as a World War II Lancaster bomber! Two potent engines would be required to power an aircraft of this size.

The tailless high delta configuration was the best compromise between a thin wing section, which could offer excellent transonic and supersonic flight characteristics, and a thicker wing root section to accommodate undercarriage and good fuel capacity. The high delta configuration also offered easy serviceability and good structural efficiency, allowing simple engine installation and easy modifications to engine and armament without affecting the basic wing structure. Also, to the benefit of the design team, considerable delta flight experience and data was available from the British parent company, Avro Manchester, which had been testing the 707 delta research aircraft prior to the design of the Vulcan tailless delta bomber.

Originally, the Canadian Department of Defense Production had issued a design contract for two prototype CF-105's from Avro, but, shortly thereafter, because of the urgency to meet the perceived Soviet threat of bombers from the north, a decision was made to skip the prototype stage altogether and the order was revised. Avro was to go directly to production with several pre-production aircraft. This approach placed considerable pressure on the design team, and a very comprehensive testing program became an obvious necessity. Totally new testing procedures would be used in the Arrow program. Of course, thorough wind tunnel testing became a priority. Through the tunnel test program, the external shape of the Arrow fuselage was refined by application of the 'Area Rule', to give the so-called "Coke Bottle" effect for the purpose of reducing supersonic drag.

Models would also play another vital design role. Launched to supersonic speeds on Nike rocket boosters, eleven free-flight models were fired between December, 1954 and January, 1957, and important data on drag and directional stability collected via the then-emerging telemetric technology. Two firings were conducted at Langley Field, Virginia, the establishment of the National Advisory Committee for Aeronautics (NACA), to take advantage of their complete, state-of-the-art tracking and telemetry equipment.

Considerable stress testing was also carried out on models. All-told, more than seventeen carefully-crafted scale models were used in the extensive design process. As actual production of the first six aircraft approached, a full- sized metal mock-up was fabricated to explore ways of facilitating actual production methods. A full-size wooden engineering mock-up was also constructed to check all equipment installation, fit and tolerances. Production machinery was designed, ordered and installed, much of it new, huge and unprecedented in the aviation industry. Meanwhile an Arrow flight simulator, connected to a state of-the-art analog computer system, the largest at the time outside the United States, was helping to gather theoretical flight characteristic data which would smooth the way to actual flight of the CF-105.

The development of the power plants chosen for the Arrow is a story in itself. The first design called for Rolls Royce RB 106 engines which were under development. When it was found that this development would be too late for the CF-105 program, Curtiss Wright J67's were substituted. Then in 1955, The U. S. Air Force announced the J67 program was to be dropped and Pratt & Whitney J75,s were chosen as a stopgap measure until the new home-grown Orenda PS13 Iroquois engines would be available.

In 1953 the PS13 Iroquois was designed by Orenda Engines Limited, later a division of A.V. Roe Canada, to power the replacement for the Avro Canuck. In a bold step, Orenda decided to jump a generation with its new design. The PS13 was to be big and powerful. At a dry weight of 4,500 lb., the Iroquois would have a five-to-one thrust-to-weight ratio, with 20,000 lb. dry thrust and 26,000 lb. with afterburner. This would create an unprecedented weight-to-thrust ratio of virtually one-to-one in the Iroquois powered Arrow.

This engine's development was not without glitches, but from original design in 1953, the problems were basically ironed out by early 1957. When ground testing was complete, a Boeing B-47 Stratojet was loaned to Avro by the USAF as a flight test bed for the new engine. One Iroquois engine had more than enough power for the B-47.

While A. V. Roe Canada was responsible for the airframe and engine development, the weapons and fire control systems were in the RCA's ballpark. At the beginning of the CF-105 project, it was understood that the package of choice was the American Hughes MX 1179 fire control system and eight Falcon missiles which had been designed for an American fighter program. However, much against the wishes of Avro, the RCAF changed its mind in favor of the Douglas Sparrow II missile then under development for the United States Navy, and the RCA Astra fire control system. This weapons package would make the Arrow more potent than any interceptor in existence. Nothing but the best for the RCAF. But, as they soon found out, it wouldn't be without cost.

By mid 1955, when the RCAF had decided upon this state-of-the-art system, Avro was forced to undertake major re-engineering to accommodate the Astra system, thus adding greatly to the financial burden imposed by the whole project. By this time, tension at Avro was beginning to increase. They knew the Astra system would prove astronomically expensive to develop. Furthermore, now all three components of the Arrow project, airframe, engine and weapons package were new, unproven, and cutting edge. The risks were suddenly much higher.

Then, a major blow to the armament program. The United States Navy dropped the Sparrow II missile project. Against the best advice from Avro, the RCAF, determined to see the best weapons system possible in the CF-105, and, apparently, regardless of the huge investment it would devour, transplanted the whole project, missiles and fire control, to Canada. As it turned out, the development cost of this package would have a significant impact on the overall cost of the Arrow program. Meanwhile, under the darkening cloud of increasing cost exacerbated by the out-of-control weapons development program, and amid growing tension in Avro administration, the airframe/engine development continued apace. The new Canadian interceptor was rolled out of the plant into public view amid glowing speeches from politicians and defense staff on October 4, 1957. According to those on the podium, it would prove more than enough to cancel out the Soviet bomber threat for the next decade.

However, an event of even greater global importance overshadowed the grand unveiling. On the same day, the Soviet satellite Sputnik was successfully launched into orbit. This event created instant, massive, technological hysteria in the west. The Soviets had leap-froged to the forefront again. Ironically, as spiraling costs conspired to sink the whole Arrow project, the successes of the testing program mounted steadily. Ground and taxi trials proceeded smoothly and, on March 25, 1958, Arrow 201 flew for the first time with Zurakowski at the controls.

The short flight-test program was almost trouble free. A couple of minor landing accidents caused by undercarriage failure and a blown tire, and a failure of the nose gear door to close seem minor in comparison to the teething problems experienced in many other fighter development programs even today.

For example, using over fifty aircraft and flying in excess of 8000 test flights, the Lockheed F-104 Starfighter test program was plagued with serious problems from the beginning. Several early 104's and their pilots were lost. Taking into account that the Arrow program never progressed past its infancy and that the five flying CF-105 Arrows accumulated among them only 66 flights and 70 hours of flight time, the fact that there were no serious problems with the aircraft itself is still a testament not only to the young Avro company and its design team, but also to the quality of the four test pilots in the program. Nevertheless, the flight-test program, which lasted less than twelve months, proceeded very smoothly and efficiently. The program was expedited by the use of ground and on-board telemetry data gathering, a technology then in its infancy. The capacious internal weapons bay of the Arrow was crammed with test instruments which allowed immediate in-flight feed-back to the pilot and those on the ground. Today we call this a "real-time" system.

The Arrow would have been an eminently developable aircraft. The introduction of micro-chip technology to replace the heavy onboard vacuum-tube computers would certainly have gained the developed Arrow a weight and space advantage resulting in substantially greater speed and range.

Another technology then in its infancy was the flight control system popularly known as "fly-by-wire". The Avro Arrow was one of the first service aircraft to use this system in which the pilot's movements were translated, via electrical switches in the control column, into electric signals which would then hydraulically introduce the movement called for in the control surfaces themselves.

Superimposed on this system was a sophisticated parallel damping system which moved the surfaces completely independent of the pilot's control column to moderate and "smooth out" the movements called for by the pilot. Eventually, the Arrow was to be able to virtually fly itself - computer controlled - with the pilot as a back-up emergency factor. Well ahead of its time, the Arrow's fly-by-wire system would not be used again successfully on a combat aircraft until the General Dynamics F-16 Fighting Falcon, which flew for the first time in 1974.

It was also the first aircraft to employ a 4000 psi hydraulic system, not replicated in any aircraft until 16 years later in the Rockwell B-1 bomber. In August, 1958, representatives of the Canadian government traveled to the United States, ostensibly to sell the Arrow or to raise funds south of the border to support the program. They came back having missed both targets, themselves the target of a strong American sales-pitch for their own aircraft and the untested American Bomarc missile.

Meanwhile, amid American offers to defend Canadian airspace if the Arrow program were indeed cancelled, the Canadian government, pointing to the costs of the project and downplaying the menace of the Soviet bomb threat, drew closer to terminating the Arrow program with the announcement that the Bomarc nuclear surface-to-air missile was coming to Canada..

Avro responded to the government's warnings of impending cancellation of the program with a final offer of $3.5 M per Arrow based on delivery of 100 aircraft. James C. Floyd, Avro Vice President, Engineering, later called this price " the deal of the century". Included would be the more powerful Iroquois and the Hughes/Falcon weapons system offered to the project just before cancellation, by the USAF at no cost. The Sparrow/Astra system had finally collapsed under its own financial obesity.

Then on February 20, 1959, still known as 'Black Friday' by many Canadians, the CF-105 program was finally cancelled. With the announcement came the direct loss of 14,000 jobs at Avro and Orenda, another 16,000 jobs with Avro's suppliers throughout Canada. It is also calculated that Avro was involved in almost 75% of all Canadian research and development at the time. Also crashing to the ground was the Orenda Iroquois engine program. With the cancellation of the Arrow, the considerable international interest which had been shown in the big engine immediately dried up.

At the time of cancellation, Arrow 206, the first Mk.2, with the Iroquois engine, was two weeks away from its first flight and a short time away from an inevitable attempt at a new world speed record. The Arrow Mk. 2 never flew. Everything relating to the Arrow program was ordered immediately destroyed, scrapped, cut up and carted away. All drawings, tools, photographs, instruments, production machinery, laboratories, and all thirty-seven aircraft - five complete and flying, one ready to fly in just two weeks, and the others in various stages of completion - were ordered destroyed.

When the Arrow program died, thousands of talented people were immediately recruited to companies out of the country. Many former Avro employees, for example, helped to put men on the moon with NASA. Some, including James Floyd, went overseas to work on the Concord project. A body blow had been delivered to Canada's fledgling aviation industry.

It was Thursday, April 25, a bare two months after Black Friday. Janus Zurakowski, the test pilot who first flew Arrow 201 thirteen months before, was on his way home from the Avro plant at Malton on Highway 401. Curiously for a test pilot, he was a nervous driver, careful not to exceed the 60-mph limit. In his rear-view mirror he noticed a truck pulling a flat-bed trailer overtaking him in the passing lane. As the truck pulled along side, he casually noted the load. There seemed something vaguely familiar about the stack of jagged white metal pieces trussed under the tie-downs. Suddenly, as he looked more closely, he made a jolting discovery. There were the numbers "2", "0", and "1" painted in black against jagged white metal pieces. Here, almost unrecognizable, was all that was left of the CF-105 Arrow. The Avro Arrow was dead. But even today, the legend of this world-beating aircraft lives on in the hearts of many Canadians.

SIDE BAR: THE BIRTH, DEATH AND LEGEND OF THE CF-105 ARROW 'A.V ROE CANADA LTD.'

Victory Aircraft of Toronto, a crown corporation, built 437 Avro Lancaster Mk. X's during World War II. Because of the outstanding quality of these aircraft, Victory caught the attention of the management of British A. V. Roe of Manchester and, shortly after war's end, Victory Aircraft was reborn as A. V. Roe Canada Ltd. on December 1, 1945.

In less than a year, A. V. Roe Canada had acquired Turbo Research Limited, another Canadian Crown company which was engaged in jet engine research and development. In 1955 A. V. Roe Canada Ltd. was split into separate Avro Aircraft Limited and Orenda Engines Limited companies, with A. V. Roe Canada Ltd. as the parent company. Orenda division produced a first-class jet engine, the Orenda, which would power the Avro's airframe division's innovative designs, and also license-built Canadian F-86 Sabres, designated CL-13, built by Canadair of Montreal, creating what many pilots judged the best Sabre of all. Orenda would also develop what was then the world's most powerful jet engine, the PS13 Iroquois, specifically to power the Avro Arrow interceptor.

During their first few years, Avro Canada produced North America's first jet transport, the prototype C-102 Jetliner, which flew for the first time on August 10, 1949, a scant two weeks after the British-designed DeHavilland Comet rose a few feet off the runway to become the world's first commercial jet to fly. It was the first product of a young, progressive aviation company which was destined to exist for a relatively short time in the rare air at the cutting edge of aircraft design and development. The Jetliner flew an amazing eight years before Boeing's 707, and represented a quantum leap in the commercial aviation field. It had all the earmarks of great success, virtually doubling the speed and altitude envelopes of existing propeller-driven airliners.

However, as the Korean conflict began, the Canadian government ordered Avro to concentrate all production on their new two-seat CF-100 Canuck long-range jet fighter. Although the development of the Avro Jetliner came to an end, the C-102 prototype flew on successfully until it was ordered scrapped in 1956. A stuck- landing-gear-forced-belly landing on its second flight proved to be the only serious problem. It would be almost ten years before any other aircraft matched its performance.

Begun in 1946, and designed to help defend Canada's vast territory, the first Avro CF-100 Canuck jet fighter prototype flew in 1950. Eventually by 1958, 692 twin-engined CF-100's were built, powered by a fine series of Orenda engines. The aircraft entered squadron service in the Royal Canadian Air Force (RCAF) in 1953, and also served in the Belgian Air Force as well.

However, in 1952, even before the sub-sonic Canuck entered service, the RCAF had set out upon a search for its replacement, eventually leading to Avro Canada Limited's greatest achievement, the CF-105 Arrow. Ironically, its greatest achievement also proved to be the ultimate downfall of A.V. Roe Canada Ltd.

An edited version of this article titled 'Canada's Supersonic Fighter Fiasco' was published in the American magazine AVIATION HISTORY as a feature article, Jan. 1998 issue.

In less than a year, A. V. Roe Canada had acquired Turbo Research Limited, another Canadian Crown company which was engaged in jet engine research and development. In 1955 A. V. Roe Canada Ltd. was split into separate Avro Aircraft Limited and Orenda Engines Limited companies, with A. V. Roe Canada Ltd. as the parent company. Orenda division produced a first-class jet engine, the Orenda, which would power the Avro's airframe division's innovative designs, and also license-built Canadian F-86 Sabres, designated CL-13, built by Canadair of Montreal, creating what many pilots judged the best Sabre of all. Orenda would also develop what was then the world's most powerful jet engine, the PS13 Iroquois, specifically to power the Avro Arrow interceptor.

During their first few years, Avro Canada produced North America's first jet transport, the prototype C-102 Jetliner, which flew for the first time on August 10, 1949, a scant two weeks after the British-designed DeHavilland Comet rose a few feet off the runway to become the world's first commercial jet to fly. It was the first product of a young, progressive aviation company which was destined to exist for a relatively short time in the rare air at the cutting edge of aircraft design and development. The Jetliner flew an amazing eight years before Boeing's 707, and represented a quantum leap in the commercial aviation field. It had all the earmarks of great success, virtually doubling the speed and altitude envelopes of existing propeller-driven airliners.

However, as the Korean conflict began, the Canadian government ordered Avro to concentrate all production on their new two-seat CF-100 Canuck long-range jet fighter. Although the development of the Avro Jetliner came to an end, the C-102 prototype flew on successfully until it was ordered scrapped in 1956. A stuck- landing-gear-forced-belly landing on its second flight proved to be the only serious problem. It would be almost ten years before any other aircraft matched its performance.

Begun in 1946, and designed to help defend Canada's vast territory, the first Avro CF-100 Canuck jet fighter prototype flew in 1950. Eventually by 1958, 692 twin-engined CF-100's were built, powered by a fine series of Orenda engines. The aircraft entered squadron service in the Royal Canadian Air Force (RCAF) in 1953, and also served in the Belgian Air Force as well.

However, in 1952, even before the sub-sonic Canuck entered service, the RCAF had set out upon a search for its replacement, eventually leading to Avro Canada Limited's greatest achievement, the CF-105 Arrow. Ironically, its greatest achievement also proved to be the ultimate downfall of A.V. Roe Canada Ltd.

An edited version of this article titled 'Canada's Supersonic Fighter Fiasco' was published in the American magazine AVIATION HISTORY as a feature article, Jan. 1998 issue.

AVRO ARROW